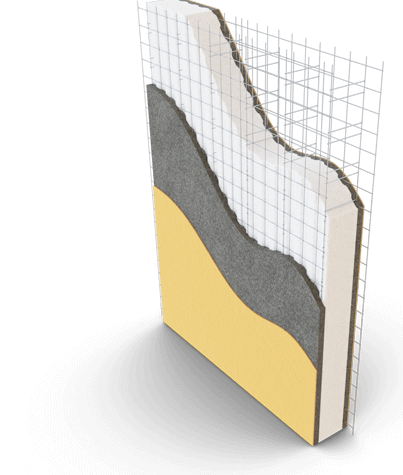

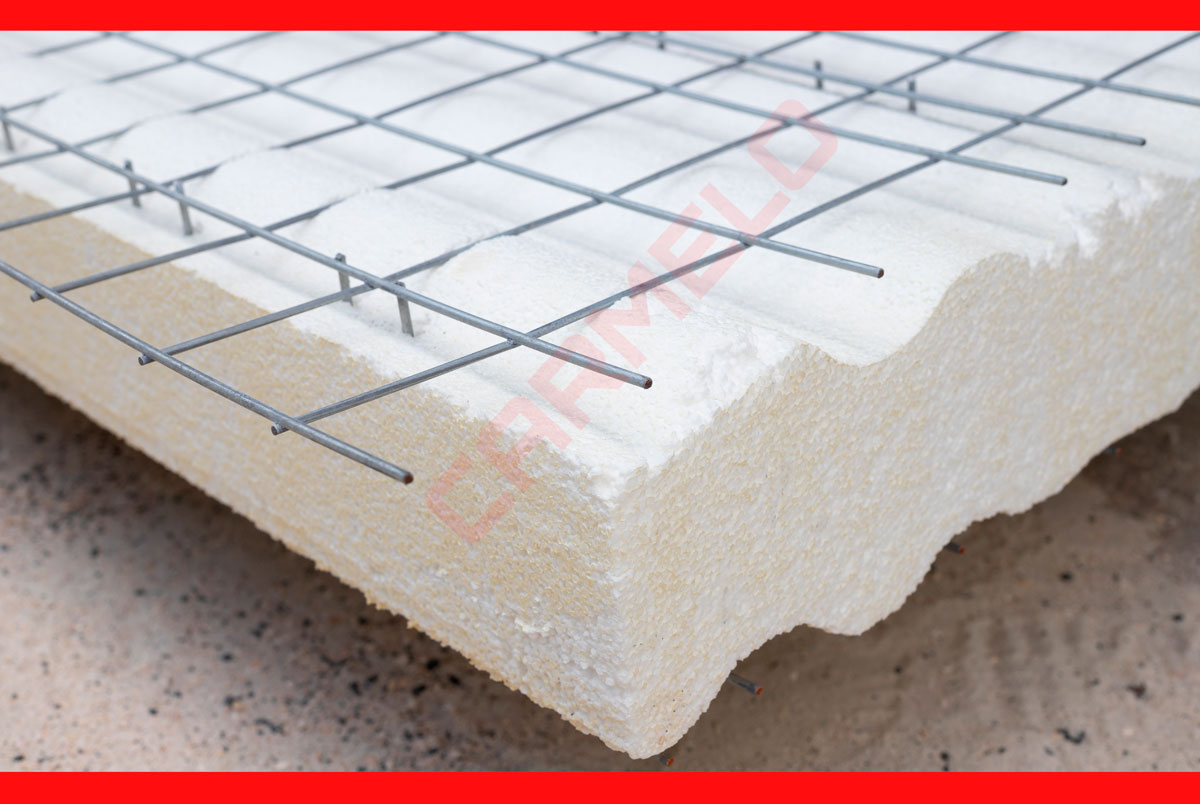

The Carmelo Structural Concrete Insulated Panels (SCIP) are made up of an electro-welded wire mesh enclosing an EPS (expanded polystyrene) core. The SCIP System is composed of high-quality panels and galvanized steel wire mesh that are installed, covered, and finished on-site with Carmelo Structural Mortar Mix. The result is a solid, energy efficient and durable construction. The panels are manufactured with a specialized machinery by Gulf Concrete Technology Corporation, owned by Ecológica Carmelo.

Types of Panels

Single Panel

The single panels are designed for walls, partitions, claddings, floors, and roofing for residential, commercial, and industrial construction. The single panel PSM, covered with the high strength concrete mortar, can be used as a load bearing structure in buildings, up to four floor heights.

Other applications are:

- Partitions and claddings in new or existing buildings

- Curtain Walls in large-sized industrial and commercial buildings as an insulated finish and protection.

- The walls are placed quickly and efficiently.

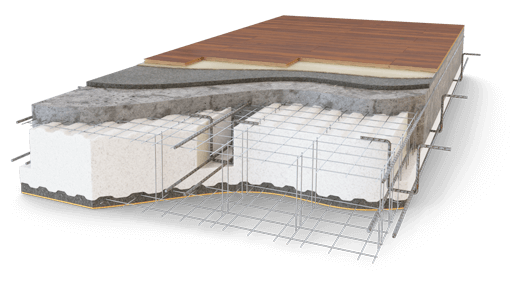

Floor and Roofing Panels

Available PSM Panels for Walls

Using the PSM Panels, you can achieve a wall height up to 13 ft. Each panel comes in 4ft width and can be put together side by side following the Technical Evaluation Report (TER) recommendations. The length is chosen by the customer according to his needs.

Wall Panel Alternatives:

PSM 80 – 8ft in height with an approximate of 6” of thickness once the wall is assembled.

PSM 100 – 10ft in height with an approximate of 7” of thickness once the wall is assembled.

PSM 120 – 13ft in height with an approximate of 8” of thickness once the wall is assembled.

Roof and Floor/ Slab Panels

Applicable Codes and Standards

The Carmelo Panels meet the PR Building Code 2018 (PRBC 2018) requirements and have the Florida Product Approval (FPA). For additional code compliance, please refer to the Section 2 in page 2 of the Carmelo Panel’s TER.

Zoning Codes and R-Value Requirements

Our Panels meet Zone 1 codes for thermal insulation as well as other Zone requirements across all US states. They also meet the R-Value Requirements in accordance with the PRECC for walls and roofs*:

- According to the International Energy Conservation Code (IECC) some of our panels meet the ideal R-Value of 30 for roofs, necessary for Part of Climate Zones 1.

- The Puerto Rico Energy Conservation Code establishes that we are Zone 1 and in the region of Tropical Sun requires that roofs need to have a minimum insulation R-Value of 15 to follow the codes.

- In Chapter 4 on residential energy efficiency, section R401.2.1 on Tropical Sun in point number 6 it speaks about the R-Value of 15 for the roofs which should meet the requirements in table 402.3 and 402.1.1.

- Our Roof Panels meet these R-value requirements and have the capacity to reach R Values up to 36 as confirmed in our TER (Table 15 in page 23 ). This provides optimal insulation and cooling for homes, helping with residential energy efficiency.

* For roof sections using Carmelo’s Panels you will need to submit an engineering design meeting the Puerto Rico Building Code 2018. Please submit this document in the form at the end of the page.

Advantages of Using Carmelo’s Panels

- Easy to handle and Quick Installation – Shortening of the construction time using the GCT SCIP System compared to those carried out with the traditional systems, optimizing the construction process, increasing productivity, and reducing labor cost.

- Architectural Freedom – We offer a full range of building panel components including: load bearing walls, partition walls, floor slabs, and roof slabs.

- Structural Capacity – Laboratory tests have proven the high load capacity of the GCT SCIP component. Compression tests with center load carried out on a finished 10ft high single panel, have shown strengths more than 20,000 lbs. / ft.

- Energy Efficient Construction with Thermal Insulation: The panel’s thermal insulation properties help regulate both hot and cold temperatures. This creates a more energy efficient home and helps reduce insurance and other costs.

- Competitive Cost: The system helps reduce the use of other materials like concrete, given that traditional projects would use between 50-80 cubic yard of concrete compared to the 25-40 cubic yards used by Carmelo’s Structural Panels.

- Reduces Waste and Other Materials – Reduces the number of products needed in comparison to traditional construction. The panels are environmentally friendly because less concrete is used, which reduces the amount of carbon footprint.

- Fire Resistant – The EPS core used for the GCT SCIP is self-extinguishing, meeting ASTM C-578. Once covered with the concrete layers on each side, the panels are protected from melting in case of a fire. A standard panel component has been rated for one (1) hour fire resistance rating according to the IBC Section 722. By increasing the mortar layer thickness, the panels can achieve up to four (4) hours of fire rating.

Main Benefits of the System in Puerto Rico and the Caribbean

- Hurricane Resistance Design – According to the results of our TER, our panels have exceeded the lab test results regarding the capacity to withstand the forces exerted by hurricanes and tornadoes with winds cycles of up to 283 miles per hour.

Seismic Response Modification Factor, a controlled simulation by Carmelo carried by DrJ Engineering LLC / Qualtim in Madison, Wisconsin.

- Earthquake Resistance Design – The Carmelo SCIP system allows seismic resistance designs for any structure in accordance with the IBC Section 1613 design code in reference to earthquake resistance. Our panels meet the ASCE 7 Sect. 12.2.1 requirements for concrete structures as specified in page Table 16 of page 25 of out TER.

- Bullet Resistance Characteristics: Carmelo’s panels have been used in the construction of federal buildings since they meet ANSI/UL/752-05 Bullet Resisting Equipment Standard for a Level III-A protection of the National Institute of Justice (NIJ) and relevant insulation values. Additional information is available on page 24 of our TER report.

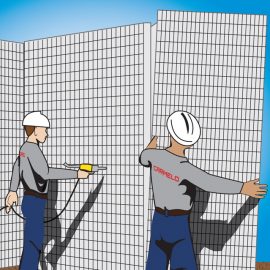

How to Build Structures Using Carmelo’s Panels

The wall panel can be easily handled by one or two people, helping the team to speed up the construction without specialized labor and heavy equipment as compared with prefabricated structures.

Plumbing and electrical piping installation

- Before placing the concrete or mortar on the panel surface, install all plumbing and electrical piping.

- Heat guns can be used to create the chases in the EPS prior to placing the electrical, communications and plumbing conduits.

- If rigid conduits are required, the steel metal mesh can be trimmed with normal steel cutting shears and afterwards replaced with portions of steel reinforced mesh.

- The insulation and steel wire can be easily cut to allow concealed placement of all utility.

Once the panels have been correctly positioned and the electrical and plumbing is in place, Structural mortar is applied to the panel surface on both sides up to three quarter (3/4) inches over the wire mesh.

For optimal panel performance, use a coat of structural mortar of three quarter (3/4) inch thickness over the wire mesh on both sides. For finishes, use a thin coat of Type N or Type S mortar.

The installation of the panels works great with our mortar application machines for an efficient construction project.

Recommended Mortars and Application Machines

The key advantages to the modern plastering method:

- TRADITIONAL:

Using Dry Mortar Mix in bags

- Reduces time it takes to prepare and apply the plastering mixes making it 3-5 times faster than the conventional method.

- Saves up to 50% cost per square yard of applied plaster/mortar

- Superior quality mortar mix complying with specifications by architects and engineers (according to federal requirements)

- Consistent surface finish throughout the project

- INDUSTRIALIZED:

Using mortar application machinery for storage, mixing, transporting, and applying plaster to surfaces.

- The key for an efficient surface finish is the capacity of the mix to prepare faster products. This is achieved by controlling the ingredients, complying with specifications, taking it direct from the factory to the job site, and using the best application equipment.

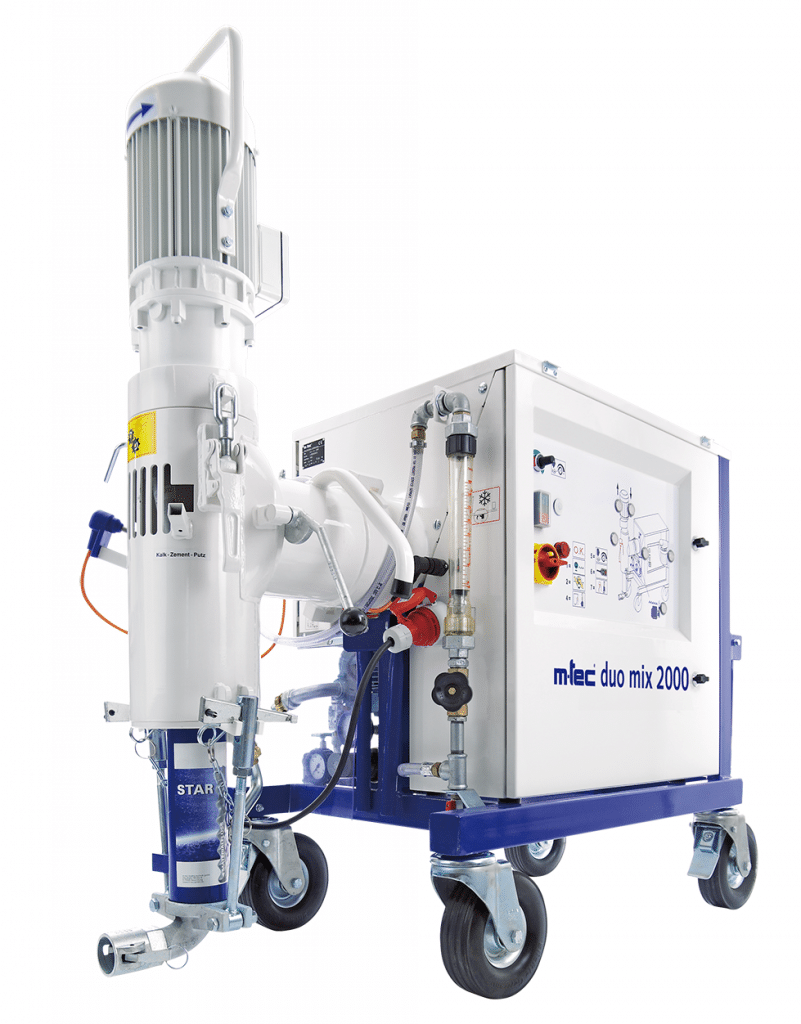

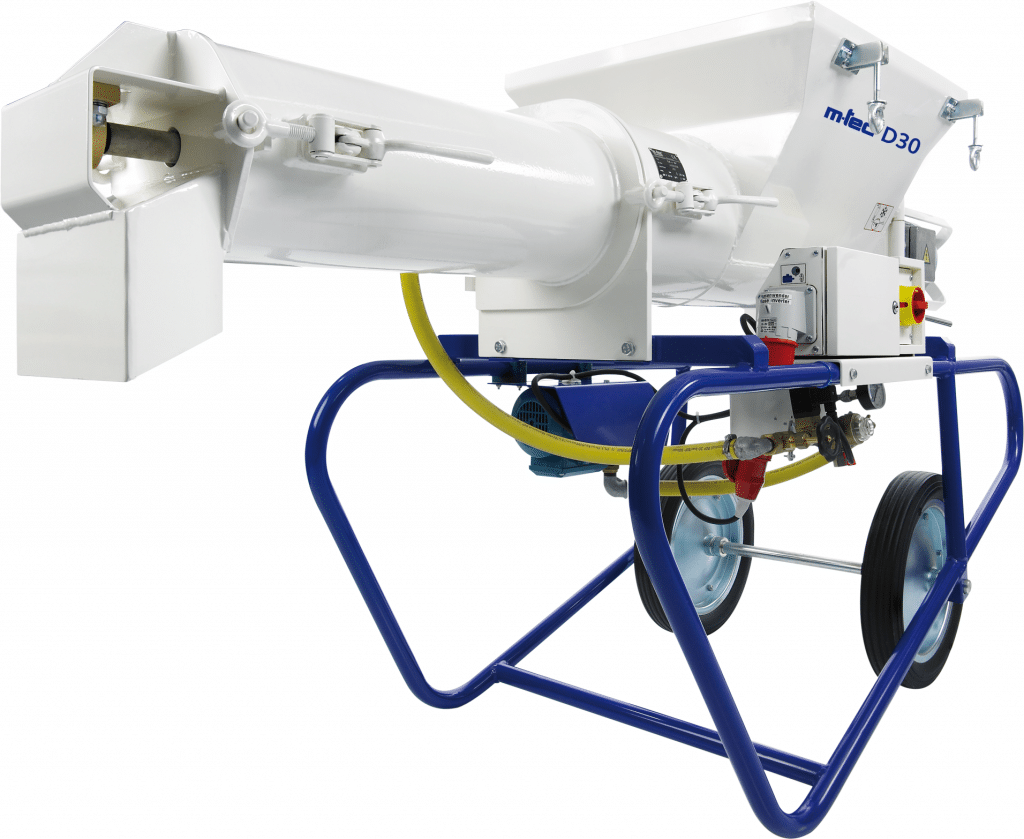

- With the use of M-tec Mixing equipment and application you cover the surfaces more efficiently.

- Construction workers and their assistants can plaster 3 (three) to 5 (five) times more area per day, reducing the time needed for the project and resulting in huge savings of money for the project.

- APPLICATION MACHINES:

Mono Mix – 220V – Single Phase Electric Power (Available for Purchase)

Duo Mix – 220V – Three Phase electric Power (Available for Purchase)

D-30 Mixer – 220V – Three Phase electric Power (Available for Rent)

22 mt² Silo Storage are available for rent and can hold 1,000 bags (Available for Rent)